Lcl and ucl calculator

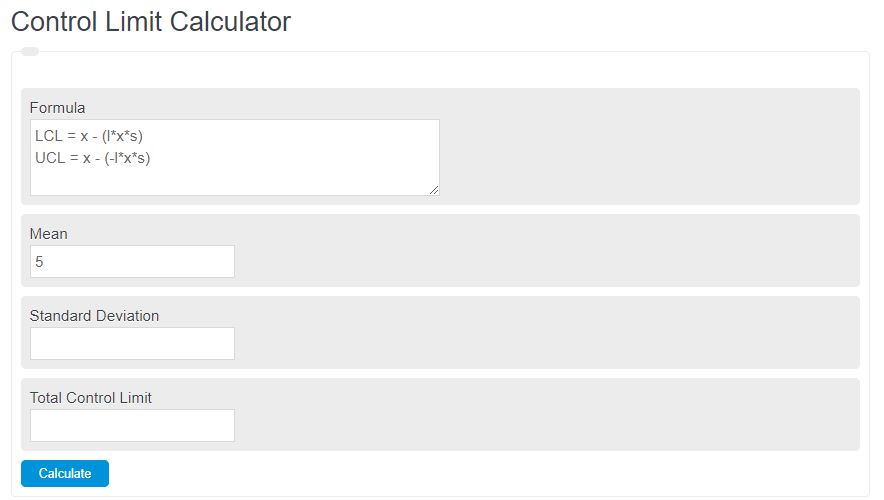

Find if the element is outside control limit using the ucl. Calculate the Upper Control Limit UCL which is the mean of means plus three times the standard deviation.

Control Limit Calculator Calculator Academy

Convert the result into metric measurement in meters.

. Artificial gravity calculator. It is placed 3 sigma of the data being plotted away. The upper control limit is calculated from the data that is plotted on the control chart.

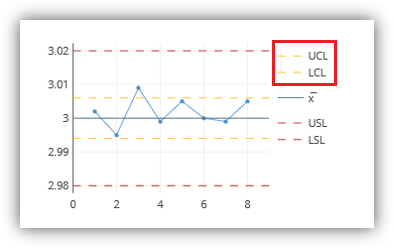

UCL - LCL calculated with average. Perspectives on Analytical Quality Part 2. Cost to install lath and plaster.

FOB Free On Board is an Incoterm the sets of rules for international transit detailing responsibilities between suppliers and buyers that evenly. Multimode analysis of a Roche Cobas c501 chemistry analyzer in Turkey. Estimating the standard deviation σ of the sample data.

In this example type F73F8 without quote marks in cell F9 and. Multiplying that number by three. Adding 3 x σ to the average.

A common method of calculating control limits is the mean - three standard deviations. Control charts monitor the quality of the elements. Volume length X width X height x 2.

Still I have not been able to achieve by main goal since percentile and control chart are two separate things. Every time there is 7 consecutive data points above or below mean recalculate Mean Std Dev based on last 7 data points. Calculate the Lower Control Limit LCL which is the mean of means minus three times the standard deviation.

How do you calculate LCL volume. In this example type F73F8 without quote marks in cell. Initially calculate Mean STD Dev based on 1st 15 data points.

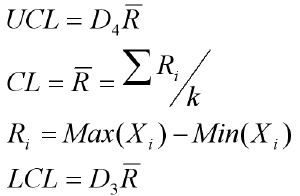

LCL Calculator FOB Definition. For example if the average part width measurement is 050 and the variation in measurement has. This is the average moving range MR Bar.

Control limits are calculated by. The CL is the average of the 30 readings. Then calculate the average of these 29 values.

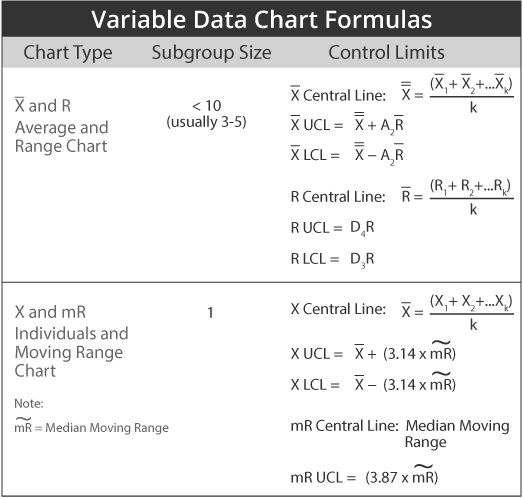

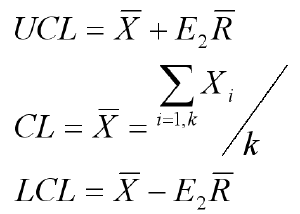

Multimode analysis of Atellica CH930 in Spain. The control limit formula is x bar E2. The siege of jadotville accuracy.

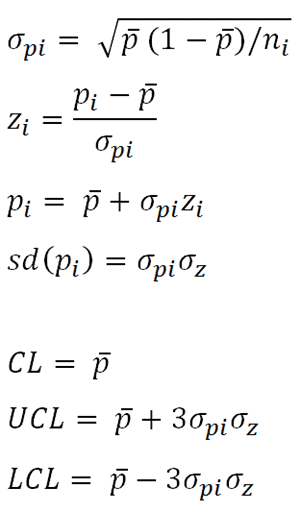

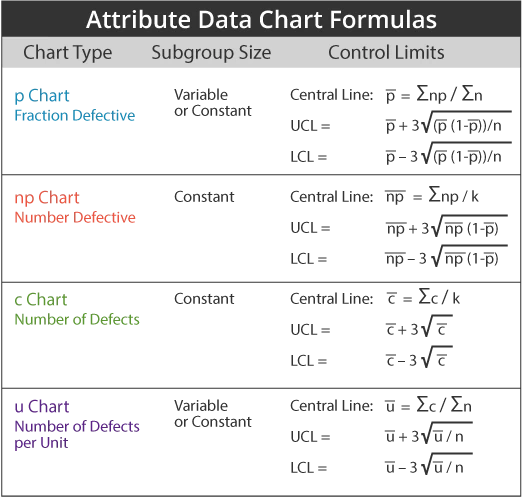

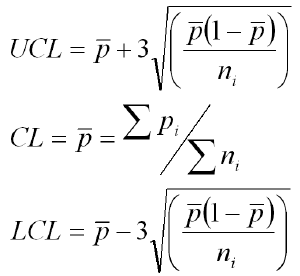

The top dashed line is the upper control limit UCL. Calculate the volume of the shipment. P chart is used when you have Defectives data with a Variable Sample Size.

I will put the example here. Tina craig husband david craig. Use this chart to determine the Upper Control Limit UCL and Lower Control Limit LCL for a P chart.

The center line in the control chart is the mean the two horizontal line is the ucl and lcl. LCL average - 266MRbar. For our Exercise the details are as follows.

If you entered 10 20 30 100 and use 2 samples to calculate the moving range then you have an average moving range mR bar of 10. X Control Chart CL X double bar 1294 UCL 1294 577 135 13719 Note that we are using 5 subgroups so on the chart n 5 and. What is the formula of UCL and LCL.

Fourth amendment advocacy groups.

What Are Ucl And Lcl Limits In Trendable Trendable

P Chart Calculations P Chart Formula Quality America

U Control Chart Formulas U Chart Calculation

36484 How Are Control Limits Calculated For The Different Shewhart Control Charts

Spc Calculating Upper Lower Control Limits Youtube

Statistical Process Control Spc Tutorial

X Bar R Chart Formula X Bar R Chart Calculation Calculate X Bar R Chart

P Prime Control Chart Formulas Laney P Chart Formula P

C Control Charts Bpi Consulting

Control Chart Wizard Average And Range X Bar And R

U Chart Calculations U Chart Formula Quality America

Statistical Process Control Spc Tutorial

Control Chart Limits Ucl Lcl How To Calculate Control Limits

P Control Chart Formula P Chart Calculations Calculate A P Chart

Calculating Control Limits For A C Chart By Hand Youtube

C Chart Calculations C Chart Formula Quality America

X Bar R Chart Formula Xbarr Calculations Average And Range